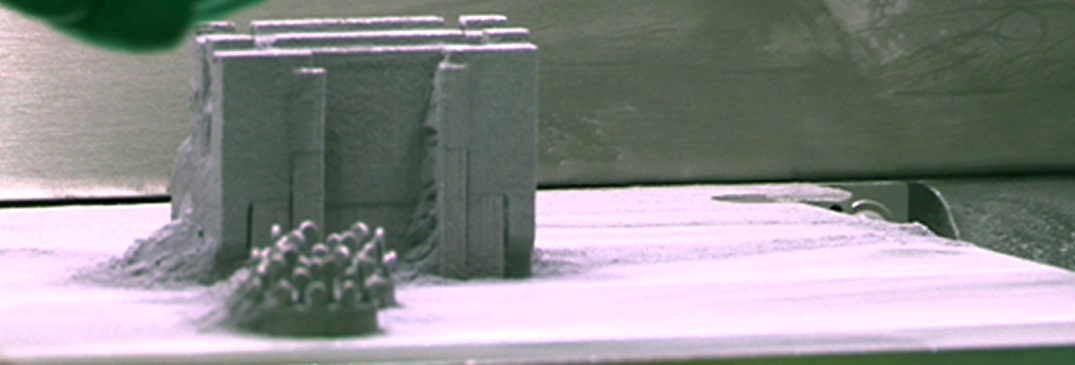

3D Printing (SLS Plastics)

Selective Laser Sintering (SLS) uses a laser to melt and solidify layers of polymer powder into functional prototypes and final parts. The laser maps the first layer of the object in the powder and selectively sinters the material. A roller spreads a new powder layer and the process repeated until the part is completed.

SLS technology enables a high degree of design freedom and engineering complexity without the need for tooling. Surface features are a bit grainy but can be polished to a smooth finish. Both custom and small-run orders can be produced in days.

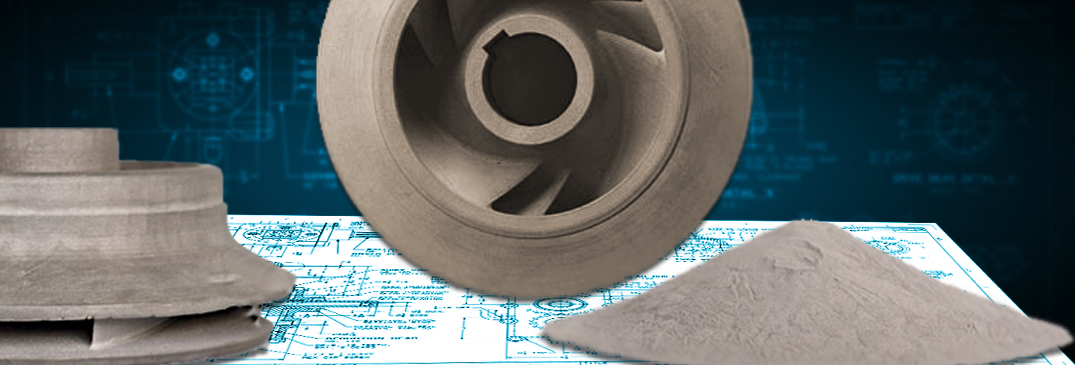

3D Printing (DMLS Metals)

Direct Metal Laser Sintering (DMLS) uses a laser to melt and solidify layers of metal powder into functional prototypes and final parts. The laser maps the first layer of the object in the powder and selectively sinters the material. A roller spreads a new powder layer and the process repeated until the part is completed. DMLS requires a support structure to anchor the object to the build platform.

DMLS is used in a variety of industrial applications (e.g. aerospace, aircraft, automotive and healthcare) to fabricate both prototypes and fully functioning final parts. The technology can reduce part quantity, enable miniaturisation and reduce part mass. Custom and small-run orders can be produced in days.

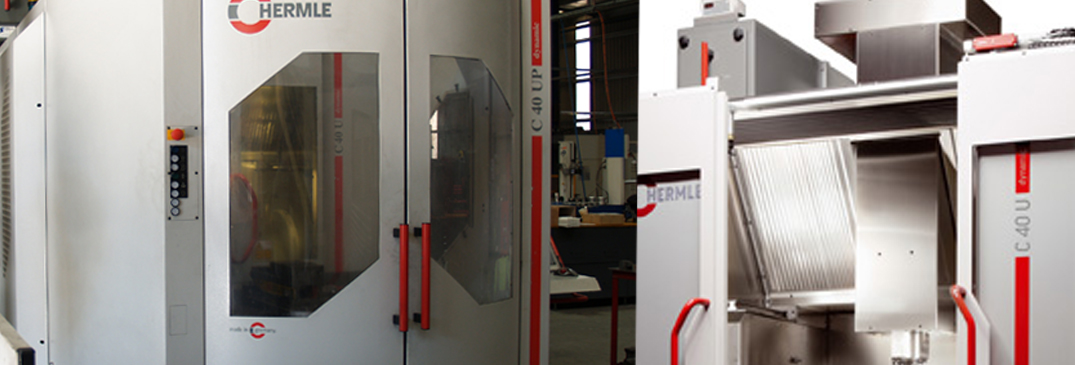

Advanced CNC Machining

Advanced CNC Machining transforms blocks of material into prototype or final parts through a controlled material removal process. Digital design instructions automate cuts while improving speed and part accuracy. “Three-axis” refers to the movement of the milling process on three different axis to rapidly cut solid blocks into final parts.

CNC machining is used across a range of consumer and industry sectors for prototyping, form and fit testing, jigs and fixtures and finished parts. Machined plastic parts are left as-milled, while metal parts can undergo further finishing.

Design & Engineering Services

Have a part concept but no CAD files? We offer an integrated services solution to ensure your part is designed with the manufacturing process in mind. Our designers and engineers will work with you through every stage of the 3D printing process, from initial concept to part design to model simulation and trial testing.

Several freeware tools (TinkerCAD, AutoDesk 123D, Blender, SketchUp and FreeCAD) are available to help you work through ideas and trial design concepts. Or try our own Free Form Design (FFD) freeware developed specifically for 3D builds using laser sintering technology.