Plastic Powders Available

PA 2200 – Industrial, Medical, Consumer Applications

The nylon PA 2200 has a balanced property profile and delivers the impact strength and durability required for high mechanical and thermal loads. The material is well suited to prototypes and working models and fully functional finished parts. Built parts have high detailed resolution if a somewhat grainy texture that can be polished to a smooth finish. PA 2200 is bio compatible and approved for food contact.

Metal Powders Available

CobaltChrome MP1 – Medical Implants, Aviation Engines

This multi purpose superalloy combines excellent mechanical properties with high corrosion and temperature resistance and high strength-to-weight ratio. The material is widely used for biomedical implants and dental parts and high-temperature aviation engines and turbines. CobaltChrome MP1 is well suited for custom working models, small series runs, spare parts and small feature parts (e.g. thin walls).

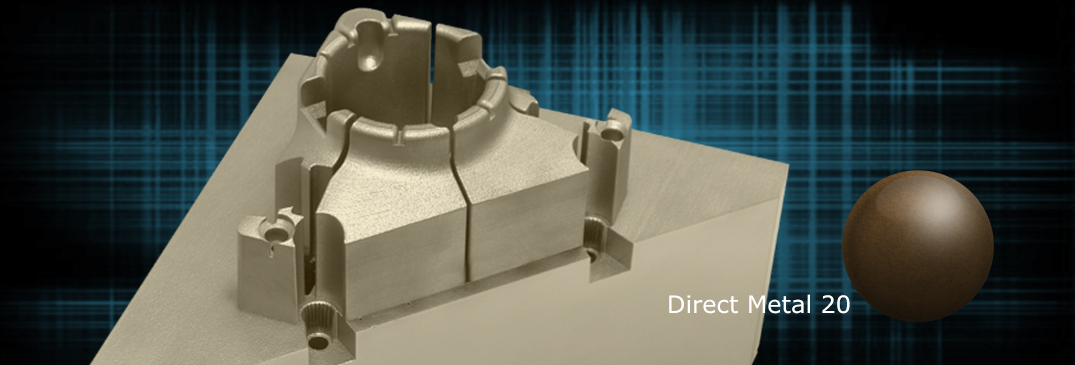

Direct Metal 20 – Tooling, Working Models

A fine-grained, corrosion resistant bronze-based metal powder, Direct Metal 20 combines good mechanical properties with excellent detail resolution and surface quality. The powder mixture enables very high part accuracies to be achieved. Surfaces can be easily post-processed and polished with little effort. Its high build speed makes Direct Metal 20 well suited for larger tools and parts, moulds and tool inserts, prototypes and working models.

MaragingSteel MS1 – Series Tooling, Engineering Applications

This steel powder is characterised by having very good mechanical properties combined with excellent hardness and strength. After the build process parts can be machined, spark-eroded, welded, micro shot-peened, polished and coated. The material is ideal for injection moulding, die casting of light metal alloys, punching, extrusion and high performance industrial and engineering parts for aerospace, aviation and motor racing.

StainlessSteel GP1 – Engineering, Industrial Applications

A fine stainless steel powder, GP1 is characterised by having very good corrosion resistance and mechanical properties (excellent ductility). The material is widely used for a variety of engineering and industrial applications. Parts made from GP1 can be machined, spark-eroded, welded, micro shot-peened, polished and coated. This stainless steel powder is ideally suited for functional prototypes, working models, small series, individual and spare parts.

Titanium Ti64 – Aviation, Biomedical Implants, Motorsports

This titanium alloy powder has excellent mechanical properties, corrosion and temperature resistance and low weight relative to strength. The powder is biocompatible and meets ASTM F1472 impurity standards. Ti64 is ideal for high-performance engineering applications such as biomedical implants and small series product runs. Parts built in Ti64 can be machined, spark-eroded, welded, micro shot-peened, polished and coated.